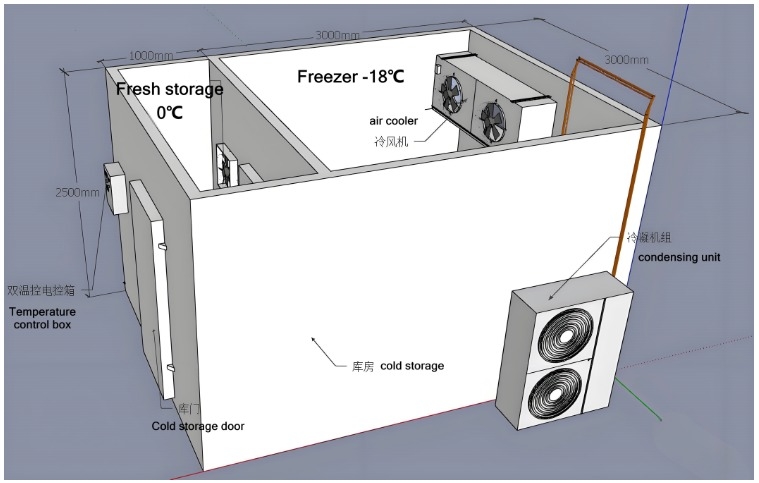

A cold storage room, also known as a walk in freezer cold room, is a temperature-controlled, customized refrigerated space designed to store goods that are sensitive to heat and need to be kept at a specific temperature to prevent spoilage, degradation, or contamination. The walk in cold storage chamber consist of below items:

Cold Storage Room Freezer

|

|

Dimension(L*W*H)

|

USUALLY CUSTOMZIED SIZE

|

|

Cooling model

|

Air cooled / water cooled / evaporation cooled

|

|

Compressor

|

Original new American copeland, Germany Bitzer etc

|

|

Refrigerant

|

R404A ,R22

|

|

Panel Thickness

|

100mm, 120mm, 150mm,200mm ,etc

|

|

Steel Plate Thickness

|

0.326mm/0.5mm/0.6mm

|

|

Service temperature

|

From -80°C To + 60°C

|

|

Cold Room Doors

|

Hinged door, Sliding door, double swing door etc

|

|

Cold Room Door Size

|

0.8*1.8 meters, door size can be customized as well

|

|

Capacity

|

3CBM~50000CBM

|

|

Applications

|

Storage Meat, vegetable, Food,Sea Food, Fish, fruits etc

|

1. PU Panel

It is the most common insulation material used for the body of cold storage warehouse. It made of a Polyurethane core and two outer layers, typically made from steel. The PU panel usually has main features as below: Superior Thermal Insulation; Durability and Hygiene(easy to clean); Lightweight and Modular( can produced by customized).

2. Cooling System

A cold room storage cooling system is a refrigeration system designed to maintain a stable, low temperature inside a highly insulated room.It works by removing heat from the interior and dissipating it outside, keeping perishable goods cool or freeze.

Compressor: The compressor is the heart of the system that GreenHealth Company work with famous brand like copeland, bitzer. And use high efficiency refrigerant: R404a.

Evaporator: The evaporator is located inside the cold room.Different capacity of cold room chamber requires different power evaporator units. For the better perfomance of walk in cold room's evaporator, all the evaporator fins use alluminum and use pure copper pipe instead of steep pipe and other types of fins.

Common Types of Cold Storage Rooms

Cold rooms are categorized based on their temperature range and function:

1. Chiller Rooms (Positive Temperature): Also name cooler room or walk in refrigerator storage room, these rooms are maintained at temperatures above freezing, typically between 0℃ and 15℃. They are used for storing fresh produce, dairy products, and certain pharmaceuticals.

2. Freezer Rooms (Negative Temperature): These rooms operate below freezing, usually from −18℃ to −28℃, and are used for long-term storage of frozen foods, meats, and vaccines. And it requies more thick pu panel to keep insulation better.

3. Blast Freezers: These are designed for rapid freezing, often reaching temperatures as low as −40℃. The fast-freezing process helps prevent the formation of large ice crystals, which preserves the texture and quality of the food.

Cold Storage Room Application

Cold storage freezer rooms have a wide range of applications across numerous industries, all centered on the fundamental need to preserve products by maintaining a controlled, low-temperature environment.

The most common and vital application is Food and Beverage Industry:

Meat, Poultry, and Seafood: Keeping these products at specific sub-freezing temperatures to prevent bacterial growth and spoilage.

Dairy Products: Storing milk, cheese, and yogurt at cool temperatures to maintain freshness.

Bakeries and Restaurants: For storing ingredients and finished products like dough, pastries, and prepared meals.

Breweries and Wineries: To control the fermentation process and store finished products at optimal temperatures to maintain quality and flavor.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!